Virtual Reality allows businesses to evaluate products before committing to physical prototypes, tooling, or manufacturing. By placing stakeholders inside the design, VR reduces ambiguity and accelerates decision-making.

How Virtual Reality Accelerates Confident Product Decisions

Validate products early without physical prototypes or tooling

Enable full-scale, immersive product evaluation for faster decisions

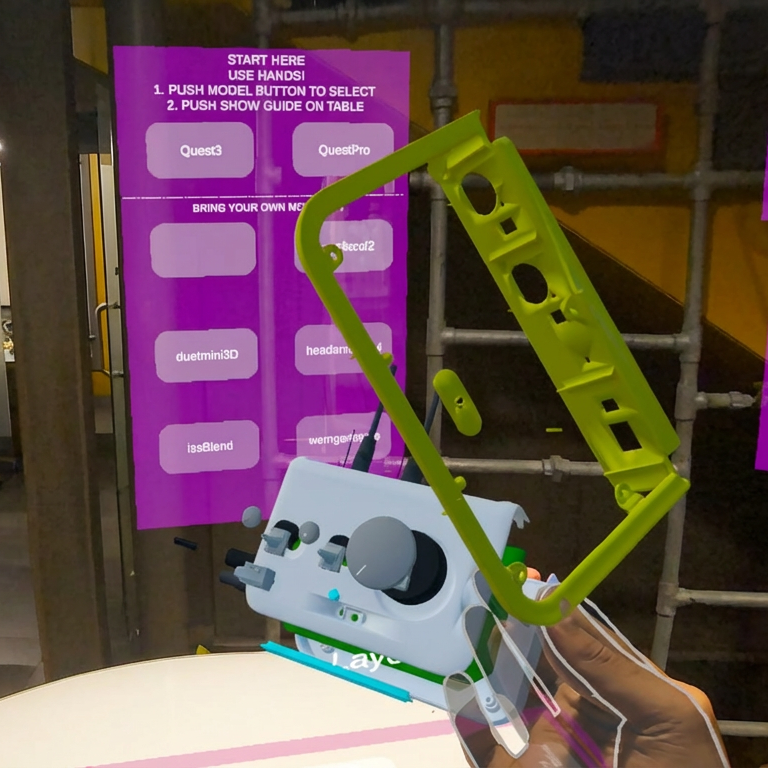

Improve cross-team alignment through intuitive, hand-based interaction

Reduce rework by identifying usability and scale issues early

Accelerate approvals with real-time VR prototyping and CMF explorationVR enables stakeholders to interact with products as full-scale, spatial objects rather than screen-based representations. This leads to faster alignment across design, engineering, and business teams. Issues related to size, usability, or proportion surface earlier in the process. Businesses benefit from fewer late-stage revisions and rework.Core Interaction Possibilities

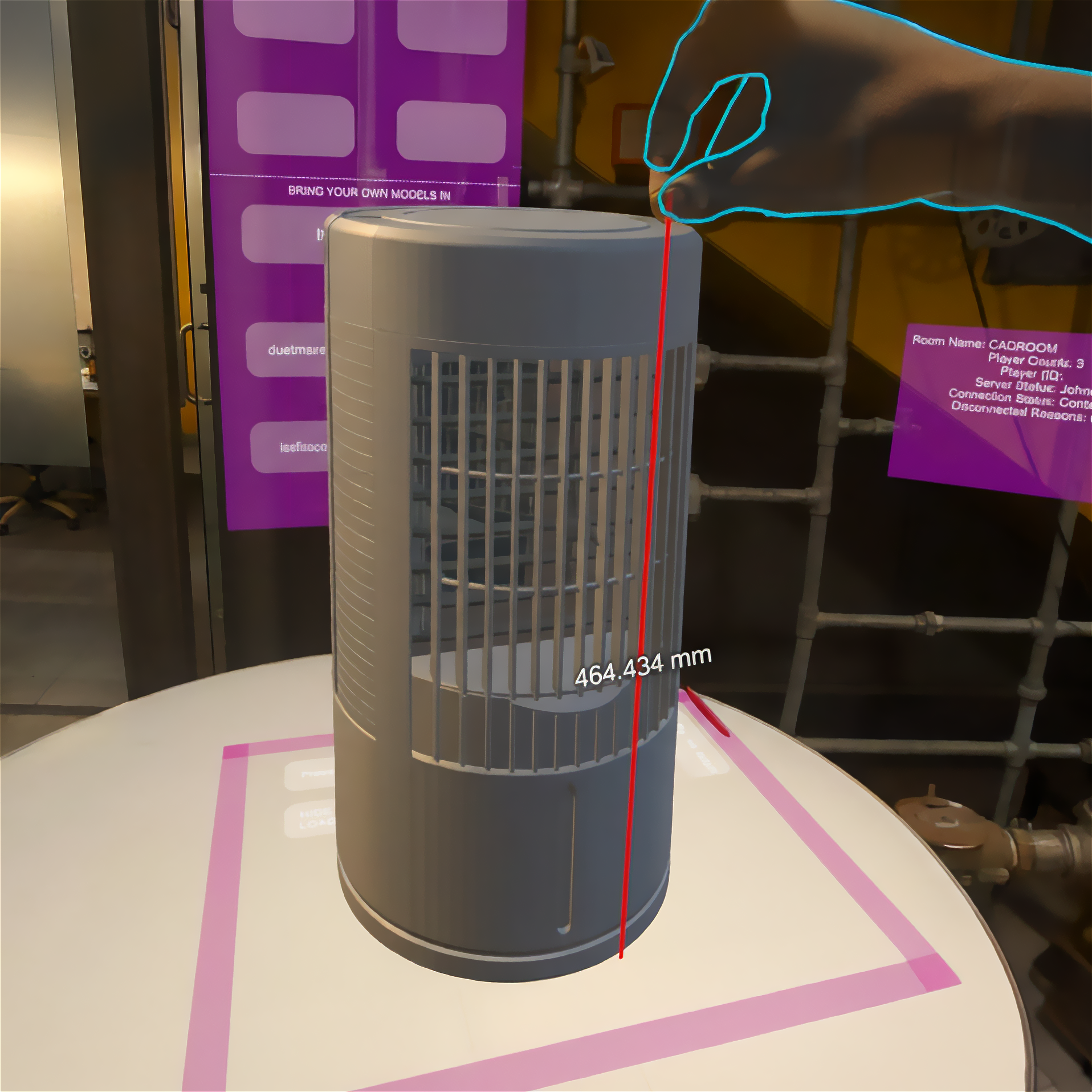

Measuring, scaling, and handling products in VR allows immediate validation of functional and ergonomic decisions. Businesses can assess feasibility before investing in physical samples. Design changes become faster and less costly. This shortens development cycles while improving confidence in outcomes.

Real-Time VR Prototyping

Real-time interaction in VR replaces static review cycles with continuous evaluation. Stakeholders experience true scale, movement, and spatial context in one environment. This reduces misinterpretation and subjective debate. Business decisions become clearer, faster, and more defensible. CMF Exploration in VR

VR allows rapid comparison of colours, materials, and finishes without producing multiple physical samples. Businesses reduce material waste and prototyping costs. Designers can test aesthetic decisions under realistic lighting and context. This ensures stronger alignment before committing to manufacturing. Similar Project